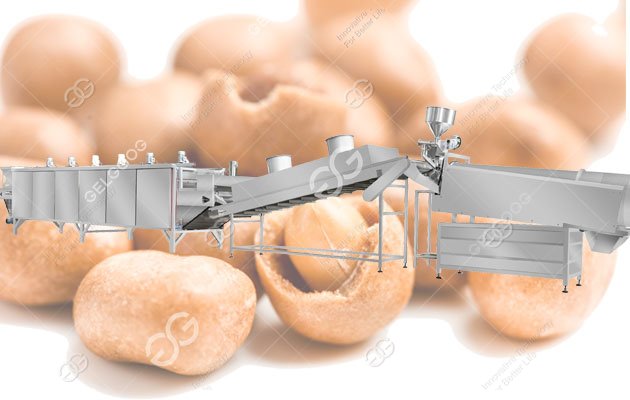

Automatic Coated Peanut Production Line Continuous Working

MOQ: 1 Set/Sets

Brand: GELGOOG MACHINERY

Supply Ability: 200 Set/Sets Per Month

Pay Method: WEST UNION L/C T/T CASH

Loading Port: Qingdao|Shanghai|Tianjin

1. Coated Peanut Production Line Flow Chart:

The technological process of the new type of coated peanuts: selection → baking → coating → frying → cooling → seasoning → packaging.

2. Performance Characteristics Of The New Type Of Coated Peanuts

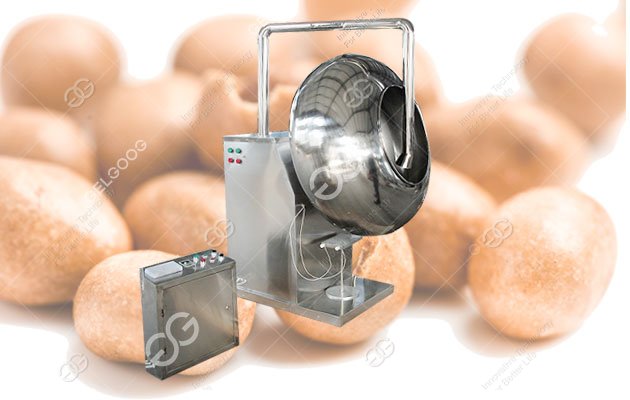

1. Advantages Of Coating Equipment

The coating equipment is adopted, and the unique structure inside the equipment greatly improves the contact opportunity of raw and auxiliary materials, the coating effect is uniform, and the defective rate of the product is reduced.

2. Application Advantages Of Excipients

Maltodextrin is added to the new coated peanut formula. Maltodextrin is easily soluble in water and can be used as a stabilizer and thickener to increase the viscosity of the solution. The solution has both flavoring and binding functions, which effectively improves the uniformity of the coating powder, ensures the appearance consistency of the coated peanuts, improves the texture tightness of the coating, and effectively prevents the coating from falling off. Inhibit browning reaction, improve the appearance of food, reduce the sweetness of the system, prevent sand returning, improve flavor, prolong shelf life, more stable product appearance, physical and chemical performance indicators, and excellent quality consistency.

3. Advantages Of Low Temperature Frying Process

The coating layer of the new-type coated peanuts is light and thin, the frying temperature is low, and the frying time is short, which reduces the risk of harmful substances, and does less damage to the nutrients of the peanuts. German reaction. Proper Maillard reaction makes the product have golden color. After the oil is blown by hot air, it is cooled to remove excess oil on the surface of the product, maintain the crisp and refreshing taste of the product, and prolong the shelf life of the product.

4. Advantages Of Seasoning Methods

The new type of coated peanuts adopts multi-layer seasoning technology, which is seasoned from three parts: solution, front powder and back powder, and the taste of the product is richer and more three-dimensional.

5. Advantages Of Continuous Production

The raw materials and semi-finished products of the new coated peanuts are always produced continuously. During the production process, the number of personnel contacting the materials is greatly reduced, and the possibility of artificially introducing microorganisms and impurities is reduced; the production cycle is shortened and the production efficiency is improved; vibrating screen and other devices It can separate the adhering materials, reduce the defective rate by 20%-30%, reduce the loss and increase the output.

The new coated peanut production line solution developed by our company can be customized according to customer needs, and the efficiency is significantly improved. wide range.

If you have needs for coated peanut processing investment or equipment upgrade, the new coated peanut production line solution developed by our company will create greater value for you.

1.Do you have manual or video for operation?

We have operation manual and video on your request.

2.Are you a manufacturer or trade company? We are professional manufacturer and supplier. Our company GELGOOG engaged in a wide range of machine business,we provide best quality machines and solutions for global users in Food Processing Machines,Packing Machines,and Other Machinery Fields.From The Single Machine To The Automatic Product Line ,From China To The Whole World.

3. Why don't person reply to me? Our person is 24hours on-line. When nobody reply you , please leave your requirements on e-mail or chat tool, we will reply you as soon as possible.

4.How do you make your price? We make the price according to our comprehensive costing. And our price will be competitive becasue we consider of material cost, labor force, exchange fluctuations rade, economic situation etc.

5.Can you guarantee your quality? Of course. We are pioneer in the manufacture of Peanut Processing Machinery, More important, we put a high value on our reputation. Competitive price with Best quality is our principle.

2.Are you a manufacturer or trade company? We are professional manufacturer and supplier. Our company GELGOOG engaged in a wide range of machine business,we provide best quality machines and solutions for global users in Food Processing Machines,Packing Machines,and Other Machinery Fields.From The Single Machine To The Automatic Product Line ,From China To The Whole World.

3. Why don't person reply to me? Our person is 24hours on-line. When nobody reply you , please leave your requirements on e-mail or chat tool, we will reply you as soon as possible.

4.How do you make your price? We make the price according to our comprehensive costing. And our price will be competitive becasue we consider of material cost, labor force, exchange fluctuations rade, economic situation etc.

5.Can you guarantee your quality? Of course. We are pioneer in the manufacture of Peanut Processing Machinery, More important, we put a high value on our reputation. Competitive price with Best quality is our principle.

Leave Message