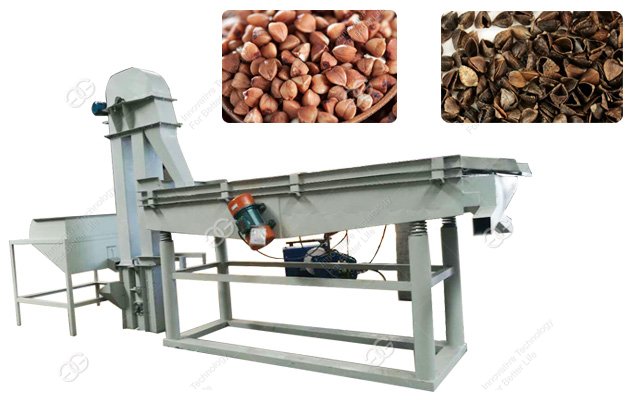

Buckwheat Cleaning Hulling Line With Stainless Steel For Sale

MOQ: 1 Set/Sets

Brand: GELGOOG MACHINERY

Supply Ability: 200 Set/Sets Per Month

Pay Method: WEST UNION L/C T/T CASH

Loading Port: Qingdao|Shanghai|Tianjin

Introduction of Stainless Steel Buckwheat Hulling Line:

This buckwheat hulling line includes buckwheat raw grain cleaning and grading machine,buckwheat shelling machine,cleaning machine,buckwheat graded packaging machine and so on. Whether raw buckwheat or steamed buckwheat, our equipment can be processed, processing 1.0-2.0 tons of raw materials per hour buckwheat.

Features of Buckwheat Huller Machine:

Related Machine:

We also have sunflower seeds shelling machine.

This buckwheat hulling line includes buckwheat raw grain cleaning and grading machine,buckwheat shelling machine,cleaning machine,buckwheat graded packaging machine and so on. Whether raw buckwheat or steamed buckwheat, our equipment can be processed, processing 1.0-2.0 tons of raw materials per hour buckwheat.

Features of Buckwheat Huller Machine:

1. Bend all the mechanical seaming technology to eliminate welding defects, sealed, wear-resistant, durable.

2. Reasonable cyclone dust removal structure, and with the installation of rotary valve with a tight, to reduce the amount of air leakage and improve the dust removal efficiency, make the work environment cleaner and environmentally friendly.

3. Selection of clean rubber ball, with high elasticity, cold resistance, anti-aging characteristics, in the winter can still be effective screening, to improve the permeability of the sieve.

4. Electrical control installed over-current, overload, short circuit protection, control cabinet comes with a socket to easily solve the mobile use of sewing machine and night lighting and other requirements.

Main Equipment of Buckwheat Cleaning Hulling Line:

Main Equipment of Buckwheat Cleaning Hulling Line:

1, Buckwheat raw materials clean up. This section of raw buckwheat to clean up, remove raw materials in the debris (including raw grain can not be processed), appropriate water and storage, raw buckwheat is divided into six levels.

2, Buckwheat shelling and cleaning. This section of raw grain grading, were shelling processing, and processing of buckwheat granules to meet the requirements.

3, The processing of buckwheat shell cleaning, removal of various impurities, including unsalted buckwheat, buckwheat, etc., through the grading according to customer requirements to complete the single-chip and complete buckwheat shell to separate, in order to improve buckwheat shell economy value.

Related Machine:

We also have sunflower seeds shelling machine.

| Processing technician | Machine | Quantity | Capacity |

|

Dehuller Unit |

Input Hopper | 2 | 400KG/H |

| Elevator | 2 | ||

| Dehuller | 2 | ||

| Sorting sieve section | 4 | ||

| control cabinet | 1 | ||

|

Cleaning&Grading |

Input Hopper | 1 |

800-1000kg/H |

| Elevator | 1 | ||

| Multifunctional impurity remover | 1 | ||

| bucket elevator | 1 | ||

| classification unit | 3 | ||

| control cabinet | 1 |

1.Do you have manual or video for operation?

We have operation manual and video on your request.

2.Are you a manufacturer or trade company? We are professional manufacturer and supplier. Our company GELGOOG engaged in a wide range of machine business,we provide best quality machines and solutions for global users in Food Processing Machines,Packing Machines,and Other Machinery Fields.From The Single Machine To The Automatic Product Line ,From China To The Whole World.

3. Why don't person reply to me? Our person is 24hours on-line. When nobody reply you , please leave your requirements on e-mail or chat tool, we will reply you as soon as possible.

4.How do you make your price? We make the price according to our comprehensive costing. And our price will be competitive becasue we consider of material cost, labor force, exchange fluctuations rade, economic situation etc.

5.Can you guarantee your quality? Of course. We are pioneer in the manufacture of Peanut Processing Machinery, More important, we put a high value on our reputation. Competitive price with Best quality is our principle.

2.Are you a manufacturer or trade company? We are professional manufacturer and supplier. Our company GELGOOG engaged in a wide range of machine business,we provide best quality machines and solutions for global users in Food Processing Machines,Packing Machines,and Other Machinery Fields.From The Single Machine To The Automatic Product Line ,From China To The Whole World.

3. Why don't person reply to me? Our person is 24hours on-line. When nobody reply you , please leave your requirements on e-mail or chat tool, we will reply you as soon as possible.

4.How do you make your price? We make the price according to our comprehensive costing. And our price will be competitive becasue we consider of material cost, labor force, exchange fluctuations rade, economic situation etc.

5.Can you guarantee your quality? Of course. We are pioneer in the manufacture of Peanut Processing Machinery, More important, we put a high value on our reputation. Competitive price with Best quality is our principle.

Leave Message